Black Chimney Caps

Stainless Steel Chimney Caps

Copper Chimney Caps

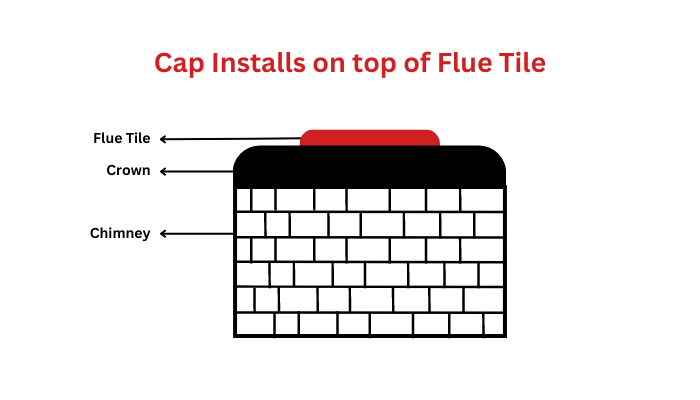

A standard chimney cap is a standard square or rectangular chimney cap that attaches to the flue tile using bolts and protects the entire top of the chimney. Standard chimney caps come in various sizes to fit your chimney’s flue tile, and can even be custom-made to fit the exact integrity of your chimney.

If your home has a square or rectangular flue tile that sticks an inch or more above your chimney crown, a standard chimney cap is a great choice to prevent water penetration, keep animals and debris out, and protect the interior of the chimney from damage. We also have custom chimney cap solutions as well.

Our standard chimney caps are available in stainless steel (including original and black powder coating) and copper. Although both of these options are incredibly durable and corrosion-resistant, copper caps do require more regular maintenance to prevent them from dulling and turning green. This process of turning green is referred to as patina, and a lot of people like the look of it with copper. Our black powder-coated chimney caps are another great option. Call us today to go over your project. We look forward to working with you!

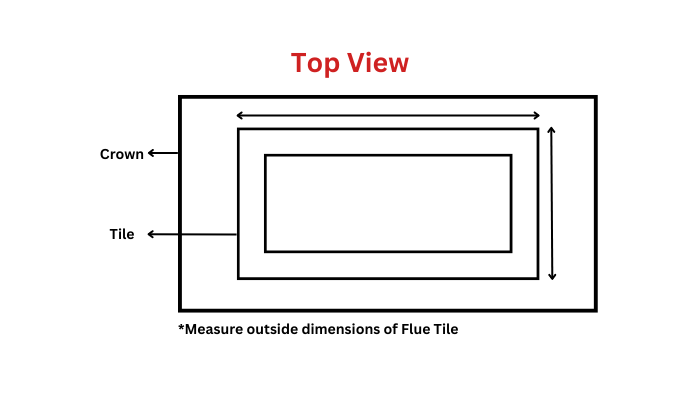

Measure the exact outside dimensions of your flue tile sticking up above the crown of your chimney.

7 Essential Benefits of Standard Chimney Caps: Ultimate Protection for Your Home

Standard chimney caps represent the most effective solution for protecting your chimney investment while preventing costly repairs. These expertly engineered caps deliver superior protection against water damage, animal intrusion, and debris accumulation that can compromise your chimney's performance. Understanding the critical importance of proper chimney protection helps homeowners make informed decisions about safeguarding their property investments.

The evolution of chimney cap technology has transformed these simple protective devices into sophisticated systems designed to address multiple challenges simultaneously. Modern standard chimney caps incorporate advanced materials science, precision engineering, and decades of field testing to deliver unparalleled protection against environmental hazards.

Why 95% of Homeowners Choose Standard Chimney Caps

Standard chimney caps attach directly to your flue tile using heavy-duty bolts, creating an impenetrable barrier against the elements. Unlike inferior alternatives, these caps cover the entire chimney top, providing comprehensive protection that saves homeowners thousands in potential repair costs annually. The strategic design ensures maximum coverage while maintaining optimal airflow characteristics essential for proper chimney function.

Our standard chimney caps feature precision-welded construction using premium materials including stainless steel and copper options. Each cap includes integrated spark arrestor screens that prevent dangerous embers from escaping while maintaining optimal airflow for efficient drafting. The manufacturing process involves multiple quality control checkpoints to ensure consistent performance across all weather conditions.

Professional installation teams report that standard chimney caps consistently outperform alternative solutions in long-term durability testing. Field studies conducted across various climate zones demonstrate superior resistance to corrosion, structural failure, and performance degradation compared to competing products in the marketplace.

3 Critical Problems Standard Chimney Caps Eliminate

Water Damage Prevention: Protecting Your Investment

Unprotected chimneys allow rainwater to penetrate masonry, causing structural deterioration that costs homeowners significant repair expenses. Standard chimney caps create a waterproof seal that prevents moisture infiltration and protects your home's structural integrity. The sophisticated drainage systems integrated into quality caps redirect water away from vulnerable chimney components.

Water damage manifests in multiple ways throughout chimney systems. Freeze-thaw cycles cause rapid expansion and contraction of moisture trapped within masonry joints, leading to accelerated deterioration of mortar and brick surfaces. Standard chimney caps interrupt this destructive cycle by preventing initial water penetration at the most vulnerable entry point.

Professional masonry contractors estimate that proper cap installation reduces water-related repair costs by 85% over a typical 15-year period. The initial investment in quality protection pays dividends through reduced maintenance requirements and extended chimney lifespan.

Animal Exclusion: Comprehensive Wildlife Protection

Wildlife intrusion affects 40% of uncapped chimneys annually, creating health hazards and property damage. Standard chimney caps feature durable mesh screens that block birds, squirrels, and raccoons while allowing proper ventilation throughout your chimney system. The precisely engineered screen dimensions prevent animal entry while maintaining unrestricted airflow.

Common wildlife problems include nesting birds that create fire hazards through accumulated debris, raccoons that damage flue liners during entry attempts, and bats that create health concerns through accumulated droppings. Standard chimney caps address these issues through comprehensive screening systems designed to exclude all common chimney invaders.

Professional wildlife removal services report dramatic reductions in chimney-related animal calls in neighborhoods with high cap installation rates. The economic impact extends beyond removal costs to include property damage repair, health remediation, and insurance claim processing.

Debris Protection: Preventing Dangerous Blockages

Falling leaves, branches, and other debris can create dangerous blockages that compromise safety. Standard chimney caps prevent accumulation that leads to poor draft conditions and potential fire hazards in your home. The aerodynamic design promotes natural debris shedding while maintaining optimal airflow characteristics.

Seasonal debris accumulation patterns vary significantly based on regional vegetation and weather patterns. Northern climates experience heavy leaf accumulation during autumn months, while coastal regions deal with storm-driven debris throughout hurricane seasons. Standard chimney caps address these varied challenges through adaptive design features.

Fire safety experts emphasize that blocked chimneys represent serious carbon monoxide risks in addition to structural fire hazards. Proper cap installation eliminates these risks while improving overall fireplace efficiency and user safety.

Professional Installation: 5 Simple Steps for Maximum Protection

Installing standard chimney caps requires basic tools and typically takes 30 minutes for experienced homeowners. Measure your flue tile's exterior dimensions precisely, select the appropriate cap size, and secure using the included mounting hardware. Professional installation services ensure perfect fit and optimal performance for decades of reliable protection.

Proper measurement techniques involve checking the outside dimensions of your terracotta flue tile that extends above the chimney crown. Add 3-4 inches to both measurements to ensure adequate overhang and weather protection. Double-check measurements in multiple locations since flues aren't always perfectly square due to settling and construction variations.

Step-by-Step Installation Process

Step 1: Safety Preparation and Assessment Begin installation by establishing safe roof access using appropriate ladder systems and safety equipment. Assess chimney condition and surrounding roof areas to identify potential hazards or structural concerns that might affect installation procedures. Document existing conditions through photographs for reference during the installation process.

Step 2: Precise Measurement and Sizing Measure flue tile dimensions at multiple points to account for irregularities in construction or settling. Record both length and width measurements, noting any variations that might affect cap selection. Consider seasonal expansion factors that can influence fit tolerances in extreme temperature conditions.

Step 3: Hardware Preparation and Positioning Organize mounting hardware according to manufacturer specifications, ensuring all components are present and properly rated for your specific installation requirements. Position the cap assembly carefully to achieve proper overhang while maintaining centered alignment over the flue opening.

Step 4: Secure Mounting and Adjustment Tighten mounting bolts gradually in a cross-pattern to ensure even pressure distribution across the flue tile surface. Avoid over-tightening that might crack terracotta materials while ensuring adequate clamping force for wind resistance. Check final positioning to verify proper overhang and alignment.

Step 5: Final Inspection and Testing Conduct comprehensive inspection of completed installation, checking all mounting points, screen integrity, and overall stability. Test cap security by applying gentle pressure in multiple directions. Document installation date and specifications for future maintenance reference.

Premium Materials: Superior Construction Quality

Standard chimney caps are available in multiple premium materials including stainless steel and copper options. Stainless steel provides excellent corrosion resistance against harsh weather conditions, while copper caps offer enhanced aesthetics with natural patina development over time. Material selection depends on climate conditions, aesthetic preferences, and long-term maintenance considerations.

The manufacturing process involves precision welding techniques that create seamless joints resistant to water penetration. Heavy-gauge materials ensure structural integrity under extreme wind loads and temperature fluctuations common in various climate conditions. Quality control procedures verify material composition and structural integrity before final assembly.

Stainless Steel: Engineering Excellence

Marine-grade stainless steel construction provides superior corrosion resistance in challenging environments including coastal regions with salt air exposure. The alloy composition specifically targets chimney application requirements, balancing strength, corrosion resistance, and thermal expansion characteristics. Advanced welding techniques create seamless joints that eliminate potential failure points.

Stainless steel caps undergo specialized heat treatment processes that enhance durability while maintaining workability during installation. The material exhibits excellent fatigue resistance under cyclic loading conditions common in roof-mounted applications. Long-term testing demonstrates consistent performance across diverse climate conditions.

Copper: Traditional Craftsmanship with Modern Performance

Copper chimney caps represent traditional craftsmanship enhanced through modern manufacturing techniques. The natural antimicrobial properties of copper provide additional protection against biological growth while developing attractive patina over time. Copper's excellent thermal conductivity helps prevent ice formation in cold climates.

Traditional copper working techniques are combined with modern precision manufacturing to create caps that meet contemporary performance standards. The material's malleability allows for custom forming while maintaining structural integrity under service loads. Proper copper cap installation provides decades of reliable service with minimal maintenance requirements.

10 Maintenance Tips for Long-lasting Performance

Regular inspection schedules help maximize the lifespan of standard chimney caps. Check mounting bolts quarterly to ensure secure attachment, especially after severe weather events. Clear debris from mesh screens during seasonal cleanings to maintain proper airflow. Proactive maintenance prevents minor issues from developing into costly repair situations.

Coastal homeowners should rinse caps with fresh water twice yearly to remove salt buildup that accelerates corrosion. Northern climates may require additional attention to ice formation that can stress mounting systems during freeze-thaw cycles. Regional maintenance schedules should reflect local environmental conditions and weather patterns.

Seasonal Maintenance Protocols

Spring Maintenance: Post-Winter Assessment Conduct thorough inspection after winter weather to identify any damage from ice, snow loads, or thermal cycling. Check for loose mounting hardware, screen damage, or structural deformation. Clean accumulated debris and inspect for signs of animal activity or nesting attempts.

Summer Maintenance: Peak Performance Preparation Verify cap stability before severe weather season begins. Clear vegetation growth that might interfere with cap function. Inspect screens for corrosion or damage that might compromise spark arrestor function. Apply protective treatments if recommended by manufacturer.

Fall Maintenance: Winter Preparation Remove accumulated leaves and debris that might retain moisture against cap surfaces. Check drainage paths to ensure proper water shedding. Inspect mounting hardware for any loosening due to thermal expansion cycles. Prepare for increased debris loads during leaf-fall season.

Winter Maintenance: Cold Weather Monitoring Monitor for ice accumulation that might stress cap structures. Clear snow loads that exceed design specifications. Watch for signs of inadequate ventilation that might indicate blockage issues. Maintain clear access paths for emergency inspections.

Proven Durability: Built to Last Decades

Our standard chimney caps withstand extreme weather conditions while maintaining structural integrity for decades of reliable protection. These professional-grade caps resist rust, corrosion, and structural failure even in harsh climates with heavy precipitation and temperature extremes. Engineering analysis demonstrates performance margins well beyond typical service requirements.

Testing procedures involve subjecting caps to simulated hurricane-force winds and thermal cycling that exceeds typical environmental stresses. Quality control measures ensure every cap meets strict manufacturing standards before shipping to customers nationwide. Independent testing laboratories verify performance claims through standardized testing protocols.

Performance Testing Standards

Structural testing protocols evaluate cap performance under extreme loading conditions including wind speeds exceeding 120 mph and thermal cycling from -40°F to 140°F. Accelerated corrosion testing simulates decades of environmental exposure in controlled laboratory conditions. Fatigue testing verifies long-term reliability under cyclic loading conditions.

Material testing ensures consistent quality across all production batches through comprehensive chemical analysis and mechanical property verification. Welding quality receives special attention through non-destructive testing methods that identify potential weaknesses before products reach customers.

Safety Features: Spark Arrestor Technology

Standard chimney caps incorporate advanced spark arrestor screens that prevent dangerous embers from escaping your chimney system. These screens feature precise mesh sizing that blocks sparks while maintaining optimal draft performance for efficient fireplace operation. The engineering balance between safety and performance requires careful optimization of screen geometry and material properties.

Fire prevention capabilities make standard chimney caps essential safety equipment for homes with wood-burning fireplaces or stoves. The integrated screening system reduces wildfire risk while protecting surrounding vegetation and structures from airborne embers. Regional fire codes increasingly mandate spark arrestor installation in high-risk areas.

Advanced Screen Technology

Mesh specifications are precisely calculated to block dangerous ember sizes while minimizing airflow restriction. Computer modeling optimizes screen geometry for maximum effectiveness across various burning conditions. Material selection ensures long-term screen integrity under high-temperature exposure.

Screen attachment methods prevent separation under thermal stress while maintaining easy access for maintenance procedures. Quality screens resist clogging from creosote buildup while providing years of reliable service. Professional cleaning techniques extend screen life while maintaining optimal safety performance.

Regional Considerations: Climate-Specific Solutions

Different geographic regions present unique challenges that influence cap selection and installation requirements. Coastal areas require enhanced corrosion resistance due to salt air exposure. Northern climates demand superior ice and snow load capacity. Desert regions need protection against sand and dust infiltration.

Hurricane-prone areas benefit from enhanced wind resistance features including reinforced mounting systems and aerodynamic design elements. Earthquake regions require flexible mounting systems that accommodate structural movement without compromising cap integrity. Wildfire zones demand premium spark arrestor systems for maximum ember protection.

Climate Zone Specifications

Coastal Environments: Marine-grade materials resist salt corrosion while specialized coatings provide additional protection. Enhanced drainage systems handle increased precipitation common in coastal climates. Wind resistance features address frequent storm conditions.

Northern Climates: Heavy-duty construction handles increased snow and ice loads. Thermal expansion joints accommodate extreme temperature variations. Enhanced drainage prevents ice dam formation that might damage cap structures.

Desert Regions: Dust-resistant designs minimize maintenance requirements in sandy conditions. UV-resistant materials withstand intense solar exposure. Thermal protection addresses extreme temperature swings common in desert climates.

High-Wind Zones: Aerodynamic profiles reduce wind loading while maintaining functionality. Reinforced mounting systems provide extra security in severe weather. Impact-resistant materials protect against wind-borne debris.

Economic Benefits: Return on Investment Analysis

Professional cost-benefit analysis demonstrates significant long-term savings through proper cap installation. Prevention of water damage alone typically justifies cap investment within the first few years of service. Additional savings from wildlife exclusion and debris prevention provide ongoing economic benefits throughout cap service life.

Insurance considerations increasingly favor properties with proper chimney protection through reduced premium rates and improved claim approval rates. Property value enhancement through proper maintenance and protection adds to overall economic benefits. Professional appraisers recognize quality chimney protection as a positive factor in property valuations.

Long-term Financial Impact

Repair cost avoidance represents the largest economic benefit from proper cap installation. Water damage repairs typically cost 10-20 times the initial cap investment. Wildlife damage remediation adds significant costs beyond initial removal expenses. Debris-related repairs and cleaning services represent ongoing costs that caps eliminate.

Energy efficiency improvements through proper draft control reduce heating costs while improving comfort levels. Professional energy audits demonstrate measurable benefits from optimal chimney performance. Reduced maintenance requirements free homeowners from recurring service costs.

Expert Recommendations for Optimal Performance

Professional chimney technicians recommend standard chimney caps as the first line of defense against weather damage and wildlife intrusion. Learn more about chimney maintenance best practices and discover how proper cap installation enhances your home's safety systems.

For comprehensive chimney inspection services, trust certified experts who understand the critical importance of complete chimney protection. Additional resources for professional chimney cleaning help maintain optimal performance year-round.

Industry standards continue evolving to address emerging challenges and improved materials technology. Professional installation certification programs ensure consistent quality across the installation industry. Ongoing research and development efforts focus on enhanced performance and simplified maintenance requirements.

Standard chimney caps deliver unmatched protection, superior craftsmanship, and exceptional value for homeowners seeking reliable chimney protection solutions. Protect your investment today with professionally manufactured caps designed to exceed industry standards and provide decades of dependable service. The comprehensive protection provided by quality caps represents one of the most cost-effective home maintenance investments available to property owners.

We Ship Anywhere USA & Canada

We Ship Anywhere USA & Canada