Chimney Liners for Gas Furnaces: Essential for Safety & Efficiency

Introduction

Ensuring that our gas furnace is operating safely and efficiently is a priority for every homeowner. A chimney liner is an essential component in achieving this goal. Many people often overlook its importance, yet a properly installed chimney liner can prevent dangerous gases from leaking into our homes and improve the overall efficiency of our heating system.

Our aim in this post is to highlight the critical role chimney liners play in maintaining a safe and functional gas furnace. We will explore how installing a chimney liner not only enhances safety by preventing carbon monoxide buildup but also supports the furnace’s performance by improving draft and reducing heat loss.

In addition to discussing the benefits, we will guide you through selecting the right type of chimney liner and share tips on proper installation and maintenance. This will ensure we make informed decisions that enhance the longevity and safety of our heating system while maintaining our home’s energy efficiency.

Key Takeaways

- Chimney liners are vital for the safety and efficiency of gas furnaces.

- Proper installation and material choice are crucial for effective performance.

- Regular maintenance of chimney liners ensures long-term safety and efficiency.

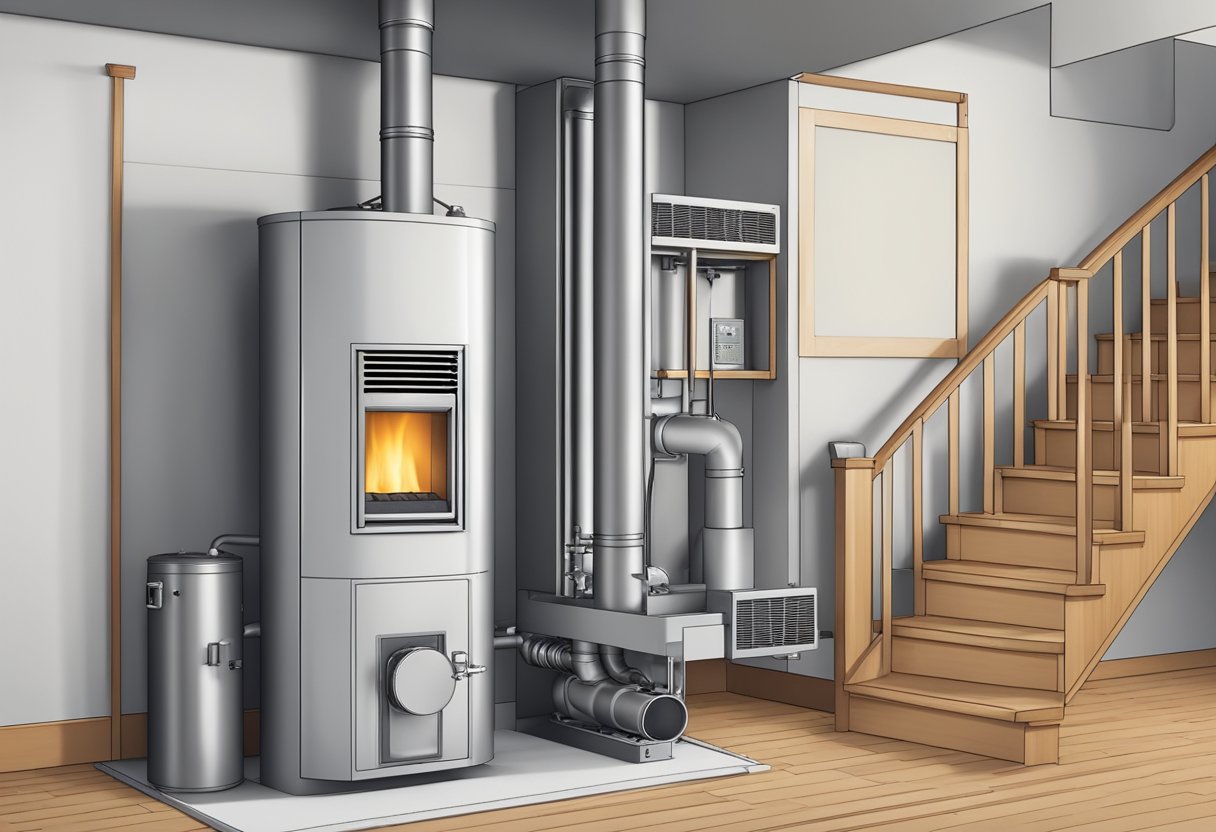

Fundamentals of Chimney Liners

Chimney liners are crucial for the safe and efficient operation of gas furnaces. They guide combustion byproducts out of the home, protect chimney walls, and improve overall appliance performance.

Role and Functions

Chimney liners serve multiple essential functions. Primarily, they contain and direct harmful combustion byproducts like carbon monoxide and other corrosive gases safely out of the home. This protection is crucial for preventing these dangerous gases from entering living spaces.

Liners also safeguard chimney walls from the intense heat and moisture produced during combustion. This protection reduces the risk of fire hazards and structural damage to the chimney. Additionally, appropriately installed liners enhance the draft, facilitating efficient expulsion of combustion gases, improving the furnace’s operational efficiency.

Types of Chimney Liners

There are primarily two types of chimney liners: stainless steel and clay. Each type has unique advantages suited to different scenarios.

Stainless steel liners are highly durable, resistant to heat and corrosion, and versatile for various fuel types. They are often a preferred choice for upgrading or repairing existing chimneys due to their long lifespan and ease of installation.

On the other hand, clay liners are more traditional and are commonly found in older homes. While they are more susceptible to cracks and moisture damage, they offer adequate protection against heat when maintained properly. For new constructions or extensive chimney repairs, stainless steel tends to be a more resilient option.

Making the right choice largely depends on the specific requirements of the chimney and furnace system.

Material Considerations for Chimney Liners

When selecting a chimney liner for gas furnaces, it’s important to consider factors such as durability, heat resistance, and corrosion resistance. Each type of liner material offers unique benefits and limitations that can impact safety and efficiency.

Stainless Steel Liners

Stainless steel liners are recognized for their superior durability and excellent heat resistance. These liners can withstand high temperatures and exposure to corrosive combustion byproducts. They are an ideal choice for gas furnaces because they ensure efficient venting of gases and help prevent potential leaks.

Stainless steel liners generally offer a long lifespan, typically ranging from 15 to 20 years. Installation is straightforward, and maintenance is minimal, making them a cost-effective solution over time. They are particularly resistant to rust and corrosion, which enhances their longevity. Given their robust performance, stainless steel liners are highly recommended for areas with harsh weather conditions.

Aluminum Liners

Aluminum liners are a lightweight and cost-effective option for certain types of gas appliances. These liners are best suited for medium-efficiency furnaces and smaller appliances. While they are not as durable as stainless steel, aluminum liners offer satisfactory corrosion resistance for low-temperature applications.

The lifespan of aluminum liners is generally shorter, around 10 to 15 years. Installation is relatively easy, but these liners may require more frequent inspections and maintenance. They are not recommended for high-efficiency gas furnaces or appliances that produce a lot of heat, as they may degrade more quickly under intense conditions. Aluminum liners serve as a budget-friendly alternative when used in the right context.

Clay Tile Liners

Clay tile liners have been a traditional choice for many years. These liners are known for their excellent heat resistance and ability to withstand high temperatures. They are constructed from ceramic materials, providing a robust barrier against the heat and gases produced by gas furnaces.

The drawback of clay tile liners lies in their relatively complex installation process, which involves masonry work. They have a lifespan ranging from 5 to 15 years, depending on maintenance and care. Clay tiles can crack and deteriorate over time, especially if exposed to rapid temperature changes. While effective in older installations, they are less popular in modern gas furnace setups due to maintenance challenges.

Cast-In-Place Liners

Cast-in-place liners offer a versatile and highly durable option for gas furnaces. Made from a mix of cement-like materials, these liners are poured and molded directly in the chimney, forming a seamless barrier. This method ensures a custom fit and maximum corrosion and heat resistance.

Cast-in-place liners can last up to 50 years if properly maintained, making them one of the longest-lasting solutions available. They improve the structural integrity of the chimney and can enhance the efficiency of your heating system. Installation requires professional expertise and may be costlier upfront. However, the longevity and minimal maintenance required often offset the initial investment.

Safety Enhancements and Efficiency Improvements

Chimney liners play a crucial role in both enhancing the safety of our homes and improving the efficiency of our heating systems. They offer protection against gas leaks and fires, while also optimizing energy usage.

Protecting Against Gas Leaks and Fires

The primary function of a chimney liner is to act as a protective barrier between the flue gases generated by our gas furnace and the masonry of the chimney. This barrier helps to contain harmful and combustible gases such as carbon monoxide, preventing them from seeping into our living spaces. Carbon monoxide can be deadly, making this safety feature essential for our homes.

Moreover, chimney liners significantly reduce the risk of chimney fires. Flammable creosote can build up along the interior walls of an unlined or poorly lined chimney. A stainless-steel liner can prevent this buildup, thus minimizing fire hazards. By preventing chimney fires, we protect our property and ensure the safety of our households.

Optimizing Energy Usage

A properly installed and sized chimney liner enhances the overall efficiency of our heating system. By improving draft and airflow, it ensures optimal performance of the gas furnace. This not only helps achieve complete combustion but also reduces energy waste. Ultimately, we use less fuel to generate the same amount of heat, leading to cost savings on our energy bills.

Enhanced energy efficiency also means that we produce fewer emissions, contributing to a more environmentally friendly home. Furthermore, chimney liners help extend the life of our chimney by protecting the structural integrity of the chimney walls, thereby reducing maintenance costs and the need for frequent repairs.

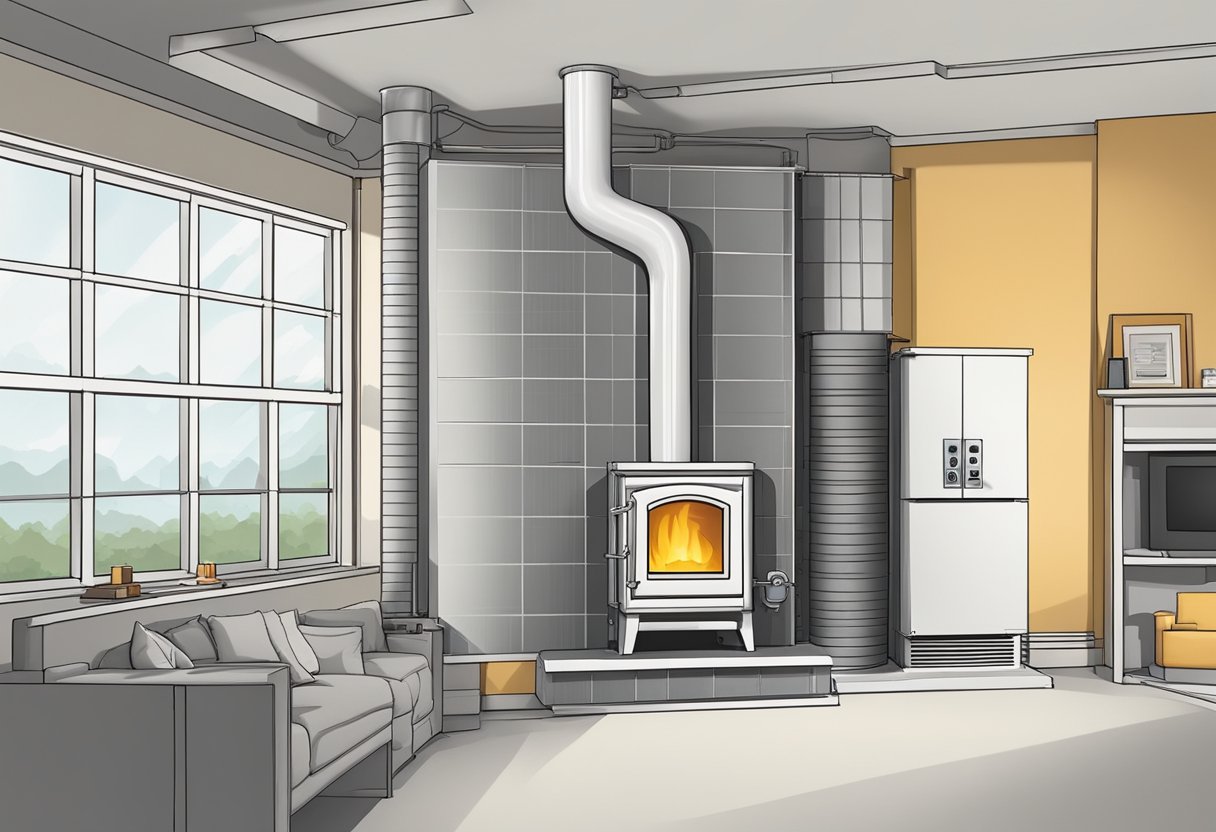

Installation and Maintenance of Chimney Liners

Proper chimney liner installation and regular maintenance are crucial for ensuring both safety and efficiency. A well-installed liner helps prevent hazardous gas leaks, while routine inspections and cleaning keep it functioning optimally.

Proper Installation Procedures

Professional installation is key to a safe and effective chimney liner. First, we need to select the correct liner material. Stainless steel liners are highly durable and suitable for multiple types of appliances, while aluminum liners work best with gas furnaces and water heaters.

Next, we ensure the liner’s diameter matches the appliance’s requirements to optimize airflow. The installation usually starts by securing the liner at the chimney top, followed by lowering it through the flue. We anchor it to the chimney walls using brackets and seal any gaps with fireproof materials to prevent leaks.

Any bends in the chimney should be carefully maneuvered to avoid kinks, which could obstruct airflow. After installation, we must test the system to verify proper ventilation and gas expulsion.

Routine Inspection and Cleaning

Annual inspections are essential to maintaining the liner’s integrity. We look for signs of wear such as cracks, corrosion, or blockages. These inspections help us identify issues that could compromise safety or efficiency before they become serious problems.

Routine cleaning is equally important. Soot and creosote buildup can create fire hazards and obstruct ventilation. Using specialized brushes, we can effectively clean the liner without causing damage. For gas furnace liners, it’s crucial to pay attention to any condensation or deposits that could indicate problems with the combustion process.

By combining regular maintenance with professional inspections, we ensure our chimney liners function safely and effectively, providing peace of mind and optimal performance.

Selecting the Right Chimney Liner

When it comes to choosing a chimney liner for your gas furnace, getting the sizing and compatibility right is essential. You also need to consider your budget and the liner’s longevity. Let me help you select the perfect liner that matches your specific appliance and chimney condition to ensure top-notch performance and safety. Explore our blog for more insights, and trust us to guide you every step of the way.

Sizing and Compatibility

Proper sizing is essential. A chimney liner that’s too small can cause poor draft and inefficient operation. On the other hand, a liner that’s too large might not properly vent gases.

We should first determine the size by measuring the height and dimensions of the chimney. For example, gas furnaces generally require a liner that matches the output of the appliance. Fireplace inserts often need a 6-inch diameter liner, while wood stoves could demand sizes between 6 to 8 inches.

Compatibility extends beyond size. Different appliances, like furnaces and wood stoves, have varied requirements that can affect the choice of liner material. A stainless-steel flue liner is often highly recommended for its rust and corrosion resistance, extending the lifespan and reliability of the setup.

Budget and Longevity Considerations

Investment in a chimney liner should balance cost with durability. Stainless-steel liners, though more expensive, offer a lifespan that can often exceed that of other materials. They come with long-term guarantees, making them a wise investment.

Conversely, aluminum liners might be more budget-friendly but typically have a shorter lifespan. It’s important to weigh immediate expenses against future costs of potential replacements or repairs. Factors like corrosion protection and resistance to harsh weather conditions play a significant role in determining the longevity of the liner.

Consulting with professionals can provide valuable insights into which type of liner fits both your budget and the specific requirements of your appliance and chimney condition.

Frequently Asked Questions

Chimney liners play a critical role in enhancing both the safety and efficiency of gas furnaces. Understand the implications of not installing a liner, the impact on operational safety, and maintenance needs.

What are the consequences of not installing a chimney liner for a gas furnace?

Without a chimney liner, the combustion gases may not be expelled effectively, leading to poor draft and inconsistent furnace operation. Over time, this can cause dangerous conditions, including a higher risk of carbon monoxide poisoning and increased wear and tear on the furnace components.

How does a chimney liner contribute to the safe operation of a gas furnace?

A chimney liner helps maintain a proper draft, which ensures that combustion gases are expelled safely. It prevents the buildup of harmful gases like carbon monoxide inside our homes and protects the chimney walls from corrosion caused by acidic flue gases, thereby extending the life of the chimney structure.

Can the efficiency of a gas furnace be affected by the condition of the chimney liner?

Yes, the efficiency of a gas furnace can be significantly impacted by the condition of the chimney liner. A well-maintained liner ensures optimal draft, allowing the furnace to operate efficiently. Conversely, a damaged or deteriorated liner can lead to poor draft and increased energy consumption as the furnace works harder to maintain the desired temperature.

What are the signs that a chimney liner needs to be replaced for optimal furnace performance?

Signs that a chimney liner might need replacement include a noticeable drop in furnace efficiency, a continuously running furnace fan, or visible deterioration such as cracks or rust on the liner. If we detect any unusual odors or accumulation of soot around the furnace, it’s time to inspect the chimney liner.

In what situations is a chimney liner mandatory for a gas furnace?

A chimney liner is typically mandatory when installing a new gas furnace if the existing chimney doesn’t meet size specifications or has signs of damage. Liner installation is also crucial when converting from a different fuel source, ensuring the chimney can safely handle the combustion gases produced by the gas furnace.

What are the typical maintenance requirements for a chimney liner associated with a gas furnace?

Routine inspections and cleanings are essential to keep our chimney liner in top shape. It’s advisable to have the liner inspected annually by a professional to check for any damage or blockages. Regular maintenance not only ensures safe operation but also extends the lifespan of both the liner and the furnace.

We Ship Anywhere USA & Canada

We Ship Anywhere USA & Canada