Anti Downdraft Chimney Cap: Enhancing Home Safety and Efficiency – Chimcare Chimney Caps

Introduction

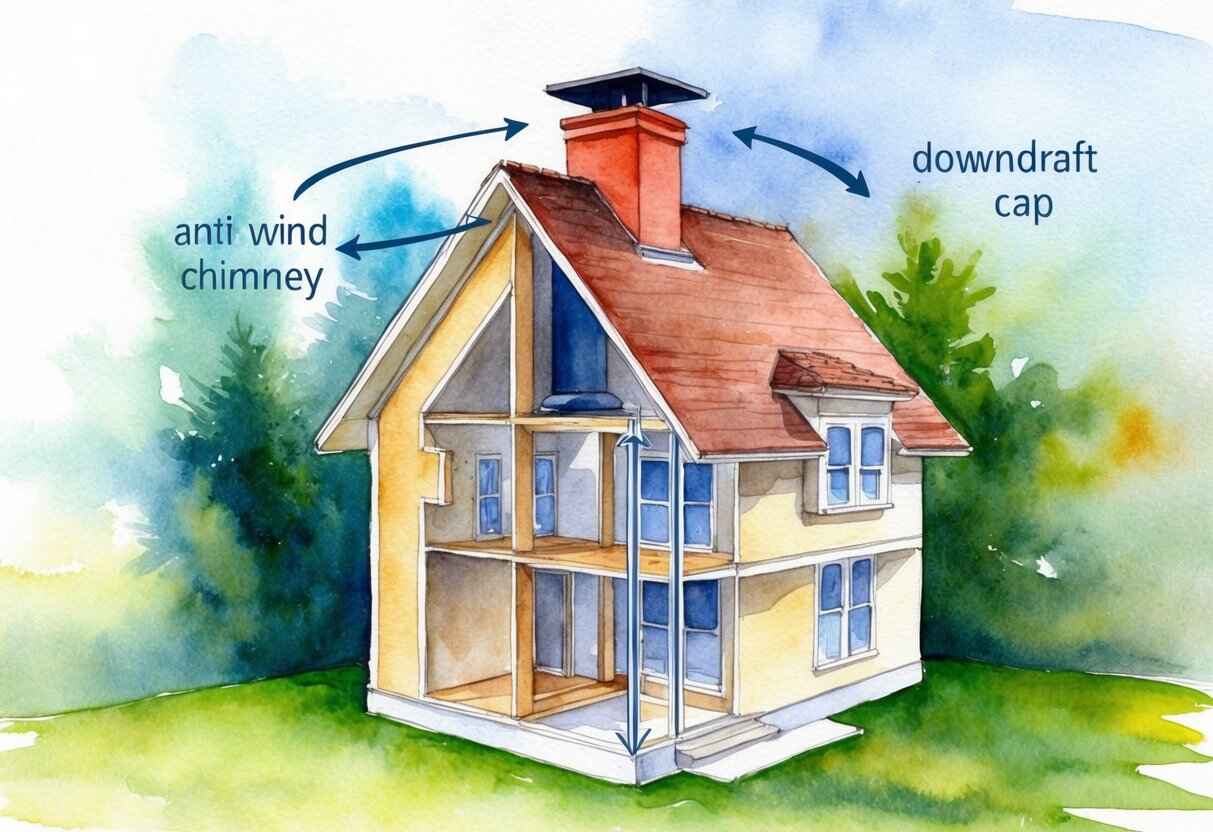

Addressing the relentless struggle with chimney downdrafts is a common issue for many homeowners. This phenomenon can lead to inefficient heating and an uncomfortable indoor environment. An anti-downdraft chimney cap is an effective solution, specifically designed to redirect wind flow, ensuring a consistent draft and preventing smoke from re-entering your living space.

The design of these caps plays a crucial role in their functionality. Typically crafted from durable materials like stainless steel, these caps are engineered without moving parts, minimizing the risk of malfunction and ensuring long-term reliability. They not only improve the comfort of our homes but also maintain the efficiency of our heating systems.

Ease of installation and maintenance are additional benefits. A proper fit guarantees optimal performance, which can make a considerable difference in the overall safety and comfort of our homes. For those seeking to solve stubborn back-drafting issues, these caps offer a practical and sustainable solution.

Key Takeaways

- Anti-downdraft chimney caps improve heating efficiency.

- Durable materials make them reliable and long-lasting.

- Proper fit is essential for effective performance.

Fundamentals of Anti Downdraft Chimney Caps

Anti downdraft chimney caps are vital for addressing wind-induced chimney draft problems. By preventing downdrafts, they enhance overall chimney efficiency and maintain a comfortable atmosphere indoors.

What Is an Anti Downdraft Chimney Cap?

An anti downdraft chimney cap is a specialized accessory installed at the top of a chimney. Our main goal with these caps is to prevent downdrafts caused by wind, which can reverse the flow of smoke and gases back into the home.

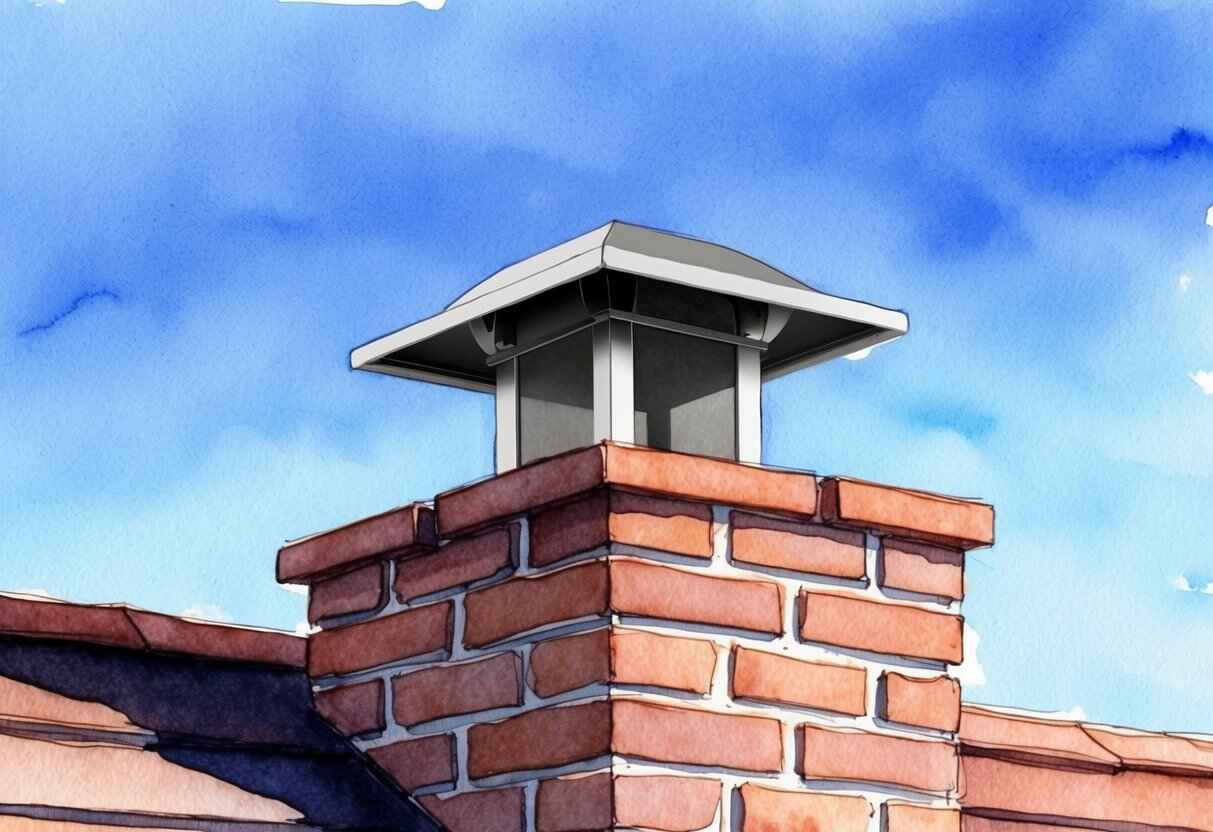

They are typically constructed from materials like stainless steel or aluminum for durability. By covering the chimney opening, they also offer protection against debris, animals, and rain, adding a level of safety and maintenance reduction.

How Do Anti Downdraft Chimney Caps Work?

Anti downdraft chimney caps work by redirecting wind flow to maintain a consistent draft. By utilizing specific designs, such as vented shapes or rotating structures, they effectively counteract negative pressure caused by wind.

This ensures smoke exits the chimney efficiently without re-entering the living space. As a result, these caps are crucial for homes in windy areas, offering a practical solution to common wind-related chimney issues. Their functional design not only enhances chimney performance but also provides environmental and structural protection.

Design and Materials

Anti-downdraft chimney caps are crafted with specific materials and designs that enhance efficiency and durability. By utilizing advanced engineering, these caps work to manage airflow and prevent unwanted downdrafts and other issues common to chimneys.

Common Materials Used

In our exploration of chimney cap materials, stainless steel is a standout. 304 stainless steel is particularly popular due to its longevity and resistance to rust and heat. These qualities are essential for any component exposed to external elements, such as extreme weather conditions.

Copper is another material often chosen for its aesthetic appeal and durability. Its ability to resist corrosion while offering a distinctive look makes it appealing for those focused on style as well as functionality. Both options ensure robust performance over time, contributing positively to the cap’s effectiveness.

Specific Design Features

Designing anti-downdraft chimney caps involves careful attention to airflow management. Many models include features that redirect wind to enhance the draft while minimizing downdraft. For instance, certain designs incorporate strategic venting or louvers to aid in airflow control.

Another important design feature is ease of installation. Caps often come with adjustable flanges or mounting brackets, ensuring a seamless fit on various chimney sizes. These thoughtful design elements not only improve functionality but also simplify installation and maintenance, making them an excellent choice for homeowners seeking both performance and efficiency.

Installation Process

Let’s explore the steps to properly install an anti-downdraft chimney cap, focusing on compatibility, necessary tools, and a detailed guide to ensure a successful installation. Each step is crucial to prevent downdraft issues and enhance chimney efficiency.

Assessing Compatible Flue Sizes

Before installation, it’s essential to measure the chimney‘s flue size. We need accurate outer dimensions to choose a cap that fits snugly and functions effectively.

The type of flue—whether single-wall, double-wall, or other—may also influence cap selection. A mismatched cap can lead to inefficiencies or hazards. Be sure to check compatibility with components such as the ceiling support box and thimble that connect the chimney to the interior.

Required Tools and Equipment

Gathering the correct tools and equipment streamlines the installation process. A basic list includes a measuring tape for precise sizing, a drill with appropriate bits for securing the cap, and safety gear like gloves and goggles.

For specific installations, housings, bolt adjusters, and sealants may be required. Ensure all tools are in good working condition to facilitate safe, efficient work. Prepare all items before ascending to the roof, as retrieving forgotten tools can be inconvenient and risky.

Step-by-Step Installation

Start with a safety inspection. Ensure the chimney is in sound condition to support a new cap. Set up secure ladder access and employ necessary safety harnesses.

- Place the cap over the flue: Verify the cap’s alignment to cover the flue completely.

- Secure the cap: Use the drill and included hardware to fasten the cap, considering the manufacturer’s guidelines for torque and spacing.

- Check for gaps or misalignments: Adjust or seal any discrepancies to prevent air leaks.

Test the installation by monitoring the chimney for effective draft and the absence of downdraft signs. An anti-downdraft chimney cap, when properly installed, will safeguard and optimize chimney performance.

Regulations and Standards

In the world of anti-downdraft chimney caps, understanding the proper regulations and standards is crucial for safe and effective operation. UL Certification and Class A chimney standards play significant roles in ensuring safety and performance.

UL Certification Explained

UL Certification identifies products that have been independently tested and meet specific safety standards. When considering anti-downdraft chimney caps, it’s essential to look for UL approval. This certification provides assurance that the product functions safely under various conditions. The UL 103HT standard is particularly important for chimneys dealing with high temperatures, ensuring that the caps can withstand intense heat released by solid-fuel appliances.

Having a UL-approved chimney cap not only meets safety regulations but also often satisfies insurance requirements. Many insurers demand products with such certifications to prevent fire hazards and ensure structural integrity. We recommend verifying the specific UL certification related to the chimney cap and its components before installation.

Importance of Meeting Class A Chimney Standards

Class A chimneys are designed for high-temperature applications, crucial for appliances burning solid fuels. Anti-downdraft caps for these chimneys must adhere to specific criteria to withstand the operational challenges posed by high heat and combustion gases.

These standards ensure that the cap can maintain its structural integrity under the extreme conditions associated with solid and liquid fuel appliances. For us, satisfying these standards translates to enhanced safety, as it minimizes the risks of chimney fires and structural damage.

It’s important that our chimney solutions not only promote efficiency but also prioritize safety through strict adherence to recognized standards. Ensure that any anti-downdraft cap is compatible with Class A chimneys to guarantee optimal performance and safety compliance.

Maintenance and Troubleshooting

Taking care of an anti-downdraft chimney cap involves regular maintenance and addressing common issues to ensure optimal performance. These steps will help maintain your chimney’s efficiency and safety.

Regular Maintenance Tips

Maintaining our anti-downdraft chimney cap begins with routine inspections. Check for any signs of rust or damage, especially around the joints and edges. This helps us catch issues early and avoid costly repairs later.

Cleaning is crucial. We should remove any debris or creosote buildup, as these can hinder proper functioning and pose fire risks. Using a soft brush or a gentle washing solution can keep the cap free from harmful residues.

It’s important to keep an eye on the storm collar and other chimney components like the Amerivent TLC. Inspect for any damage or wear, ensuring they are tightly sealed to prevent water intrusion. This includes checking the insulated chimney sections, which can corrode over time if not cared for properly.

Troubleshooting Common Issues

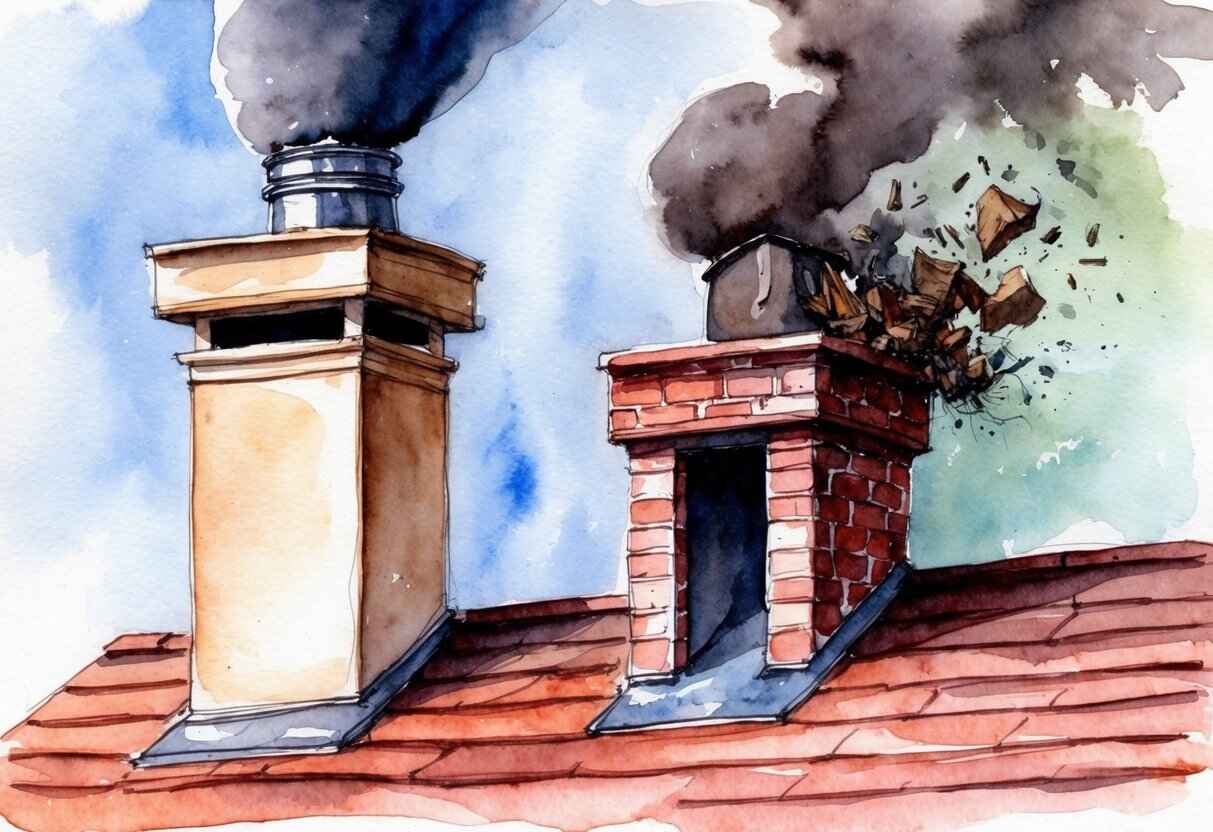

Downdrafts can occur due to improper installation or damage to the cap. If we notice smoke backing up into our home, it’s important to check the alignment and condition of the cap.

Loose fittings or incorrect sizing may cause issues. We should verify that the anti-downdraft chimney cap is securely attached and fits well with the chimney flue. Consulting with a professional might be necessary if these adjustments don’t resolve the problem.

Noises, such as clunking in strong winds, often indicate a need for lubrication or adjustment. Regularly rotating the cap can help alleviate these issues and ensure smooth operation.

By addressing these problems promptly, we maintain optimal performance and prolong the life of our chimney components.

Frequently Asked Questions

Anti-downdraft chimney caps are essential for addressing backdraft issues, improving draft, and providing protection against weather and debris. Below, we address some common questions regarding these chimney accessories.

What is the best chimney cap to prevent downdrafts?

Choosing the best chimney cap depends on specific needs. Options like the Vacu Stack Anti-Downdraft Cap are popular due to their effectiveness and simplicity, as they have no moving parts that may fail.

How do you install an anti-downdraft chimney cap?

Installation usually involves securing the cap to the chimney flue with screws or clamps. It’s crucial to follow the manufacturer’s instructions closely to ensure proper fit and function. We recommend hiring a professional if you’re uncertain.

Are there any reliable reviews for anti-downdraft chimney caps?

Numerous online platforms provide reviews for these products. It’s beneficial to consult multiple sources to get a balanced view on performance, ease of installation, and durability before making a purchase.

What are the different types of chimney caps available?

There are several types, including standard caps, draft-improving caps, and wind directional caps. Each type serves unique functions such as debris prevention, draft enhancement, and downdraft reduction.

Can installing a chimney cap improve draft issues?

Yes, many homeowners find that specific chimney caps, especially those designed for draft improvement, significantly mitigate draft problems. These caps help to maintain consistent air flow, preventing smoke from entering the living space.

Do wind directional chimney caps effectively stop downdraft?

Wind directional chimney caps are specifically engineered to combat downdrafts. Their design allows them to redirect wind flow and enhance draft efficiency, making them an excellent option for homes in windy areas.

We Ship Anywhere USA & Canada

We Ship Anywhere USA & Canada