13×13 Chimney Cap: Ensuring Optimal Ventilation and Safety – Chimcare Chimney Caps

Introduction

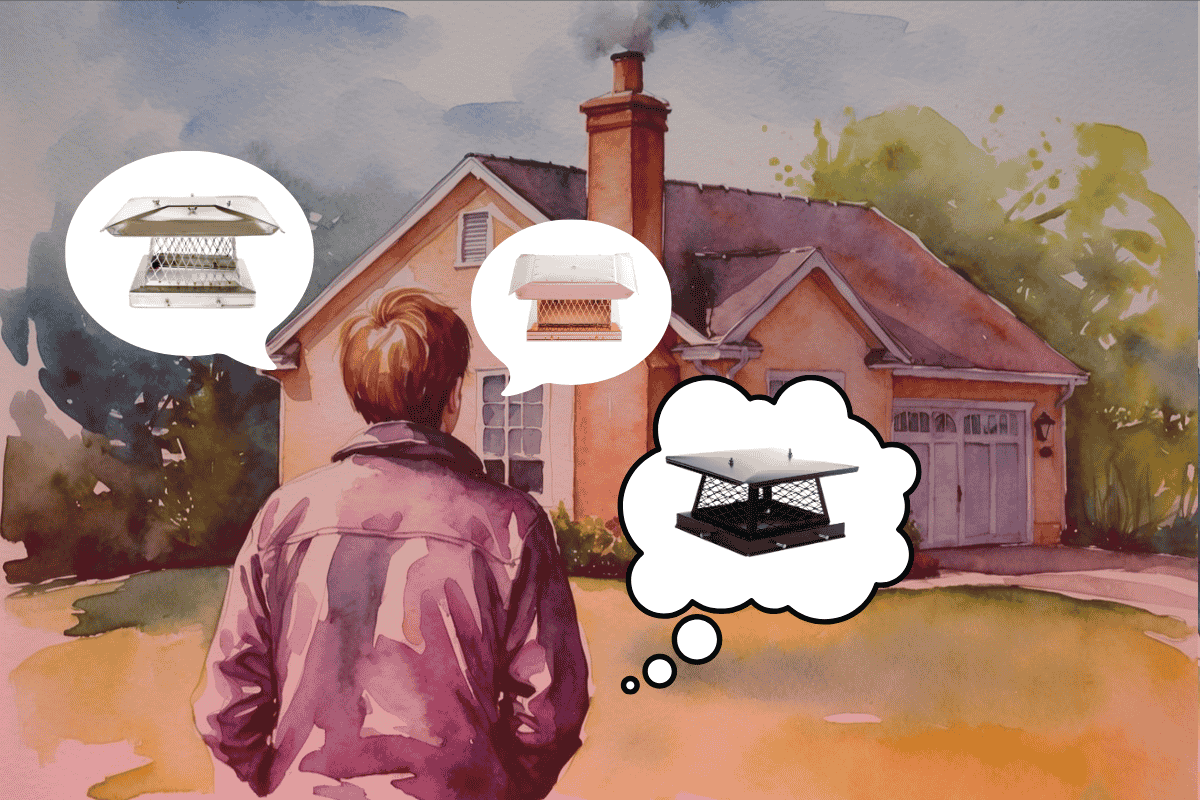

Choosing the right chimney cap is more important than you might think. Not only do these caps protect your chimney from weather elements, but they also prevent small animals from entering your home through the flue. Among the different sizes available, the 13×13 chimney cap stands out due to its balance of versatility and practicality.

The 13×13 chimney cap fits over a flue tile and is often crafted from durable materials like stainless steel, offering longevity and minimal maintenance. By investing in this size, homeowners ensure their fireplaces operate safely and efficiently. This size also features designs that help keep sparks contained, reducing the risk of rooftop fires.

For those who want a reliable option with the ease of installation, 13×13 chimney caps often come with the necessary hardware. This ensures a secure fit for square flue tiles without requiring professional help in most cases. Let’s delve into what makes this chimney cap a favorite among homeowners and dive into our tips for selecting, installing, and maintaining your 13×13 chimney cap.

Key Takeaways

- The 13×13 chimney cap is versatile and practical.

- It offers durability and safety features.

- They include hardware for easy installation.

Understanding Chimney Caps

Chimney caps play a crucial role in protecting and enhancing the functionality of chimney systems. Some chimney caps help in preventing downdrafts, safeguarding against wildlife, and ensuring that weather elements like rain don’t affect the chimney’s interior. Let’s explore their purposes, common types, and materials.

Purpose and Benefits

Depending on the chimney cap your order, some caps cater to solving issues with keeping water and animals out, where a chimney cap like a wind directional or a high wind cap adds an additional feature of solving downdrafts, which can push smoke and cold air back into our homes. These caps also act as barriers against rain and snow, protecting the chimney flue from moisture that could cause damage over time.

A chimney cap reduces debris accumulation, minimizing the risk of blockages and potential fires. It also acts as a guard against animals, such as birds, racoons and squirrels, which might seek shelter in the chimney.

Types of 13 x 13 Chimney Caps

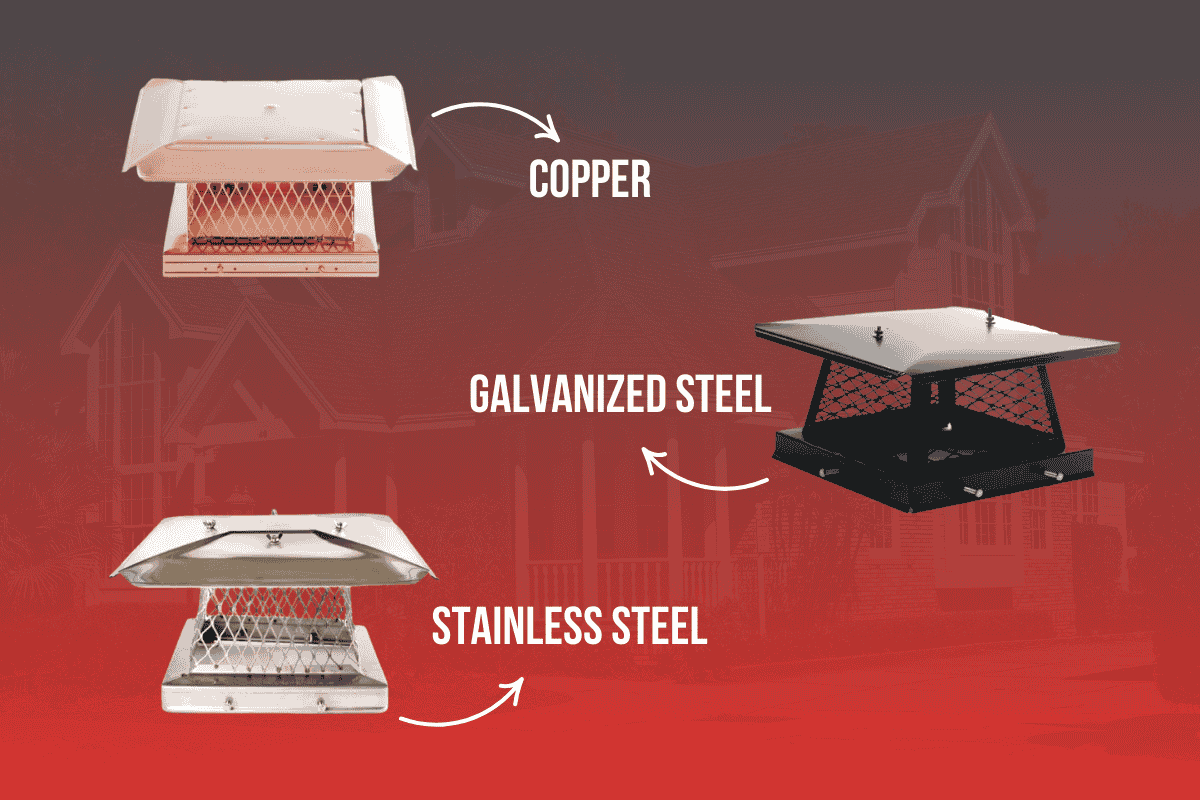

Materials Used for 13×13 Chimney Caps

At Chimcare, we offer 13×13 chimney caps crafted from premium materials to ensure long-lasting protection and durability. Each material is chosen with care to suit different climates, aesthetic preferences, and budget considerations:

- Stainless Steel: Stainless steel chimney caps are a favorite for their unparalleled durability and resistance to rust and corrosion. Perfect for all weather conditions, these caps provide reliable, long-term protection for your chimney. Plus, they maintain their sleek appearance over time with minimal maintenance.

- Copper: Copper chimney caps are both functional and stylish. They stand out for their natural beauty and unique ability to develop a patina that adds character over time. Copper is also highly durable and resistant to the elements, making it a great choice for those looking to enhance their home’s curb appeal.

- Galvanized Steel: Galvanized steel caps are an economical option, offering reliable protection against weather and debris. Although not as long-lasting as stainless steel or copper, they provide a cost-effective solution for homeowners on a budget.

No matter the material you choose, all our 13×13 chimney caps are designed to provide superior protection, preventing rain, animals, and debris from entering your chimney. Explore our selection to find the perfect cap to meet your needs!

Selecting the Right 13×13 Chimney Cap

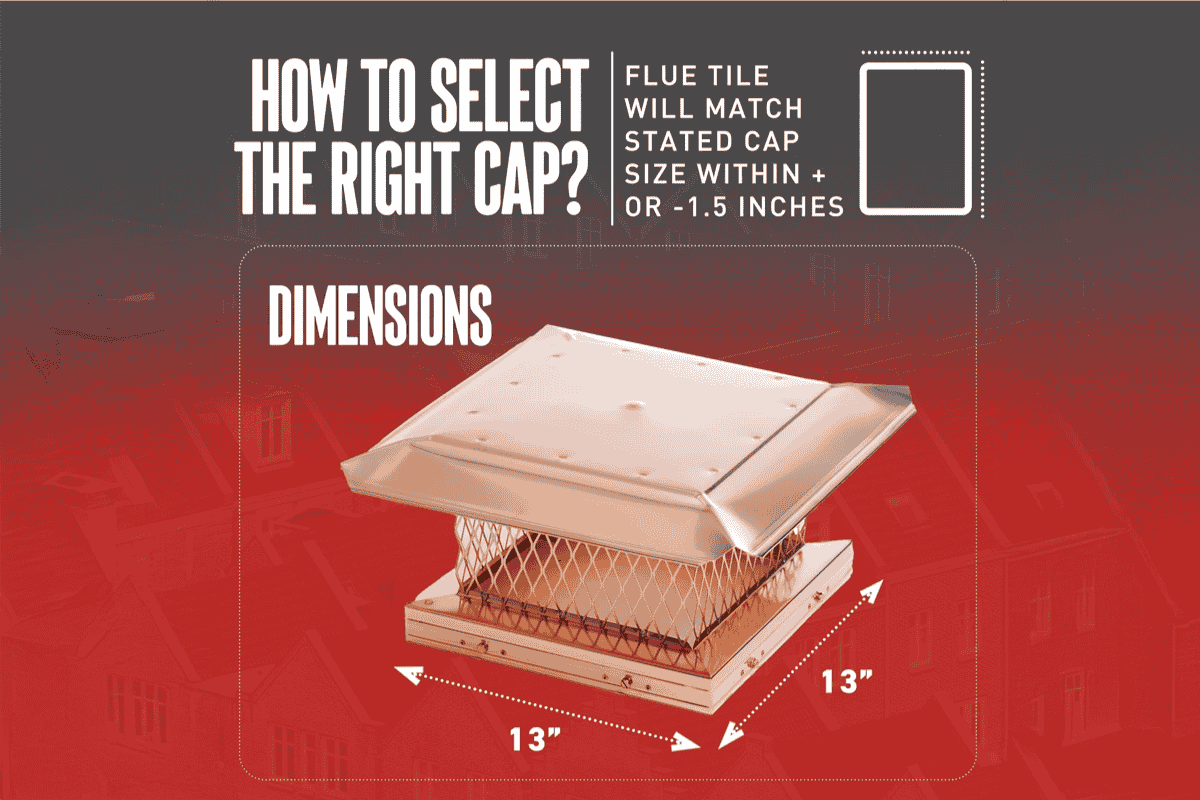

Choosing a 13×13 chimney cap involves considering sizing and compatibility specifics to ensure it securely fits the chimney and meets our functional needs.

Sizing and Fit

Ensuring the correct size is essential when selecting a chimney cap for effective and secure protection. Chimney caps are typically designed to accommodate slight variations in flue dimensions, allowing for a snug and reliable fit. Most caps are made to fit flues with measurements within +/- 1.5 inches of the stated cap size.

- Measurements: Accurately measure the outside dimensions of your flue tile to determine the appropriate size.

- Installation: Chimney caps usually include installation hardware to simplify attachment and provide adjustable options for a secure fit.

- Material Variations: Stainless steel caps offer excellent durability and resistance to weather, while galvanized steel provides a more budget-friendly option, albeit with a shorter lifespan.

Choosing the right size and material ensures your chimney cap provides long-lasting protection and enhances your chimney’s performance.

Compatibility with Your Chimney

For optimal performance, it’s essential that our chosen chimney cap is compatible with our specific chimney type and structure. The material of the cap can affect this compatibility. For example, stainless steel is often preferred for its resistance to rust and corrosion, which makes it suited for various environments.

Flue shape and construction also play significant roles. Some chimneys may require specific attachment methods or design features to handle potential issues like downdrafts or creosote build-up. Understanding these needs helps us select a cap that not only fits physically but also complements the operational demands of our chimney.

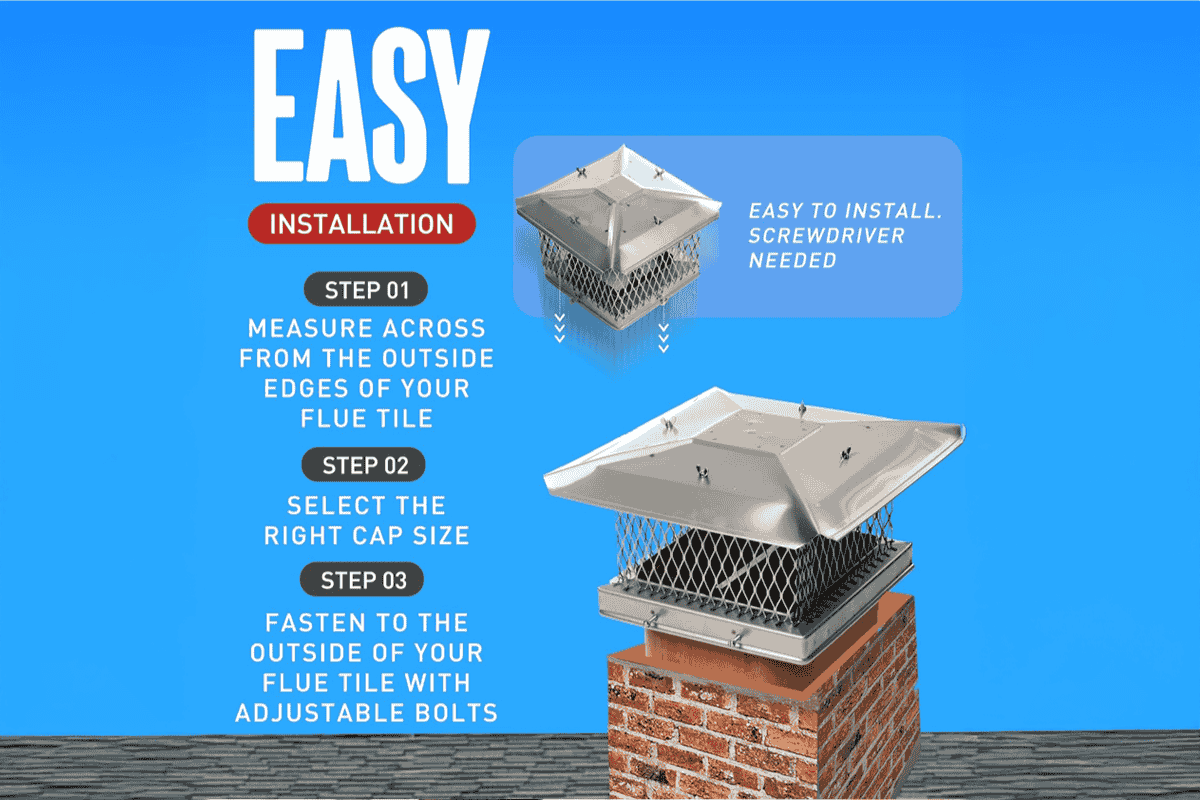

Installation of a 13×13 Chimney Cap

Installing a 13×13 chimney cap is a straightforward process that provides vital protection for your chimney. Ensuring you have the right tools and following a precise step-by-step guide will make the installation quick and effective.

Required Tools

To adequately install a 13×13 chimney cap, certain tools are essential for a smooth process. We recommend the following:

- Screwdriver: A flathead or Phillips depending on your cap’s screws.

- Measuring Tape: For accurate sizing of the flue.

- Work Gloves: To protect your hands from sharp edges.

- Ladder: Offers access to your chimney, ensuring stability and safety.

- Adjustable Wrench: Useful for any adjustable fittings your chimney cap might require.

Having these tools on hand before starting will streamline the installation and ensure the cap fits snugly and operates efficiently.

Step-by-Step Guide

- Safety First: Begin by ensuring the fireplace is off and the chimney is cool. Wear gloves and secure a stable ladder to access the chimney.

- Measure the Flue: Use a measuring tape to confirm the dimensions of your flue fit the 13×13 chimney cap. Correct measurement ensures the cap aligns properly.

- Prepare the Cap: Detach any detachable parts, such as the top cover. Adjust the cap’s size if it’s a universal model, ensuring the flue is covered adequately.

- Position the Cap: Set the cap on the flue so that its mesh extends over the flue’s edge, preventing wildlife entry.

- Secure the Cap: Tighten the screws with a screwdriver, or as required; use an adjustable wrench. Ensure stability by checking all screws are firmly in place.

By following these detailed steps, we ensure that our chimney cap is securely installed, providing protection from elements and critters. Adjustments are minimal with proper preparation and tool use.

Maintenance and Care

Maintaining a 13×13 chimney cap is essential to ensure optimal performance and extend its lifespan. By prioritizing routine inspections and regular cleaning, we can prevent common issues such as blockages, corrosion, and animal intrusions.

Routine Inspection

Routine inspection of our chimney cap helps us detect any signs of wear or damage early. We should examine the cap for rust, cracks, or loose components. It’s important to ensure there are no gaps between the cap and chimney, which could allow water and debris to enter. Checking the cap after severe weather can help identify any damage caused by wind or hail. Keeping an inspection schedule, ideally during the fall and spring, ensures that our cap is functioning correctly before heavy use in winter.

Cleaning Your Chimney Cap

Cleaning the chimney cap is crucial to maintaining efficient airflow and preventing smoke from backing up into our home. We must clear out leaves, twigs, and soot from the cap’s mesh screen, which can become clogged over time. Using a wire brush gently removes buildup without damaging the material. It’s advisable to wear safety gear to protect against dirt and sharp edges. Regular cleaning not only improves performance but also reduces fire hazards associated with obstructed chimneys. A good practice is to align cleaning with our scheduled inspections for thorough maintenance.

Troubleshooting Common Issues

When working with a 13×13 chimney cap, certain issues may arise that require swift attention. Two critical concerns are managing airflow to prevent drafts and ensuring that water ingress does not compromise the cap’s performance.

Dealing with Draft Problems

Draft problems are a common challenge with chimney caps. If we notice unwelcome drafts, a primary step is checking for blockages. Debris, such as leaves or soot, can hinder airflow, making it essential to regularly clean the cap and flue.

Incorrect cap size can also cause drafts. It’s vital to ensure a proper fit around the chimney. If the 13×13 cap isn’t sealing well, we might need to adjust or replace the cap.

Finally, high winds can create pressure imbalances. In such cases, we should consider using a wind-resistant cap design. Adding a top-sealing damper can also enhance draft control by regulating air entry.

Preventing Water Ingress

Water ingress can quickly deteriorate chimney integrity. Our first line of defense is ensuring the chimney cap is intact. Regular inspection for rust or damage is crucial since a corroded cap may let water seep through.

Proper installation is key to avoiding water issues. We must ensure the cap’s top edges extend beyond the chimney to direct water away. Verifying that seals and fasteners are secure also helps prevent leaks.

In areas with heavy rain, adding a drip edge can provide extra protection. It’s a simple addition that helps channel water off the sides and away from vulnerable joints. Implementing these measures can significantly reduce water-related risks.

Frequently Asked Questions

Understanding the specifics of chimney caps, including sizing and materials, helps us make informed decisions. We address common concerns about functionality, available materials, and the installation process.

How do I determine the correct size cap for my chimney?

To ensure a proper fit, we measure the length and width of the flue at its widest points. Common dimensions for chimney caps include 13″ x 13″, which fits various masonry chimneys. Using a tape measure can help us obtain accurate dimensions.

What are the differences between chimney caps and flue caps?

Chimney caps cover the entire top portion of the chimney, offering protection against weather and critter intrusion. Flue caps specifically protect the flue opening and are crucial for optimizing airflow and preventing backdrafts. Both play distinct roles in maintaining chimney system efficiency.

Can installing a chimney cap improve fireplace functionality?

Installing a chimney cap can enhance fireplace functionality by preventing water entry and debris accumulation. This aids in maintaining proper airflow and improving draft quality, leading to a more efficient and safer fireplace operation.

What materials are best for a durable chimney cap?

Stainless steel and galvanized steel are popular choices due to their durability and resistance to rust. Stainless steel offers greater longevity, whereas galvanized steel provides a more economical option with corrosion protection. Material choice often depends on environmental conditions and budget considerations.

What should I consider when choosing a chimney cap with a damper?

When selecting a chimney cap with a damper, we assess the compatibility with existing chimney structures and the ease of operation. Dampers help improve energy efficiency by sealing the chimney when not in use, reducing heat loss.

What is involved in the installation process for a chimney cap?

Installing a chimney cap typically involves securing the cap to the chimney top with screws or clamps. It’s crucial to check for a snug fit to prevent drafts and ensure stability. Regular maintenance, like clearing debris, further supports the cap’s protective functions.

We Ship Anywhere USA & Canada

We Ship Anywhere USA & Canada