Flue Chimney: Essential Maintenance Tips for Homeowners

Introduction

A chimney flue is an essential component of our home’s heating system, responsible for directing smoke and gases safely out of the building. Understanding the role of the chimney flue helps us ensure our fireplaces and heating appliances function efficiently and safely. Without a properly functioning flue, we risk harmful smoke entering our living areas and damaging the chimney’s structural integrity.

We need to recognize that chimney flues come in different types, each with specific installation and maintenance requirements. Routine inspections and proper care can significantly extend the lifespan of our flues and enhance safety. This article will guide us through the basics of chimney flues, their importance, and what we need to know for effective upkeep.

Key Takeaways

- A chimney flue efficiently channels smoke away from our homes.

- Regular maintenance and inspections are crucial for safety.

- Understanding flue liner options helps optimize performance.

Understanding Chimney Flue Basics

Chimney flues play a crucial role in the safe operation of fireplaces and stoves. They are designed to facilitate the efficient removal of combustion gases and smoke while protecting the chimney structure itself.

Components and Functionality

A chimney flue consists of several key components, primarily the flue liner, which is a protective layer that runs inside the chimney. This liner directs smoke and gases safely outside, minimizing the risk of heat transfer to combustible materials surrounding the chimney.

The smoke chamber, located just above the fireplace, compresses the smoke and directs it upward into the flue. Proper airflow is essential; it ensures that combustion gases escape efficiently, reducing harmful buildup within the home. If the flue is compromised, it can lead to health risks, including smoke inhalation.

Materials used in chimney flues vary. Common options include clay tiles for flue lining, metal liners for flexibility, and cast-in-place liners for durability. Each type ensures safety while enhancing the overall efficiency of the chimney structure.

Types of Flues

Chimney flues can be categorized into several types based on construction and material. The most common are masonry flues, typically built from brick or stone, which provide robustness and insulation. Another prevalent type is the metal flue, often made of stainless steel, suitable for prefabricated chimneys.

We may also encounter double-walled flues, which feature insulation between two metal walls to prevent heat loss and condensation. Additionally, direct vent flues draw air from outside, providing better ventilation for efficient combustion.

Choosing the appropriate type of flue is crucial for ensuring proper ventilation, which significantly affects the efficiency and safety of our heating systems.

Safety and Regulations

Safety and compliance with regulations regarding chimney flues are essential to protect our homes and health. We must be diligent in managing chimney fires, avoiding carbon monoxide risks, and adhering to building codes.

Preventing Chimney Fires

Chimney fires are a serious concern for any wood-burning appliance. They often result from creosote buildup, a byproduct of burning wood. Regular inspections are vital; we recommend checking chimneys at least once a year.

Key prevention steps include:

- Cleaning: Remove creosote deposits to lower fire risks.

- Proper Installation: Follow guidelines for flue sizing and placement.

- Use of Approved Fuels: Burning seasoned wood reduces creosote generation.

By taking these precautions, we can significantly lower the risk of chimney fires.

Carbon Monoxide Risks and Management

Carbon monoxide (CO) is a colorless, odorless gas produced during combustion. When our chimney systems malfunction, we risk exposure to this harmful gas.

To mitigate CO risks, we should:

- Ensure Ventilation: Open windows during operation to provide air flow.

- Install CO Detectors: Place alarms on every floor, especially near sleeping areas.

- Regular Maintenance: Schedule annual chimney sweeps and inspections to ensure proper function.

This proactive management is crucial in preventing carbon monoxide poisoning, which can be life-threatening.

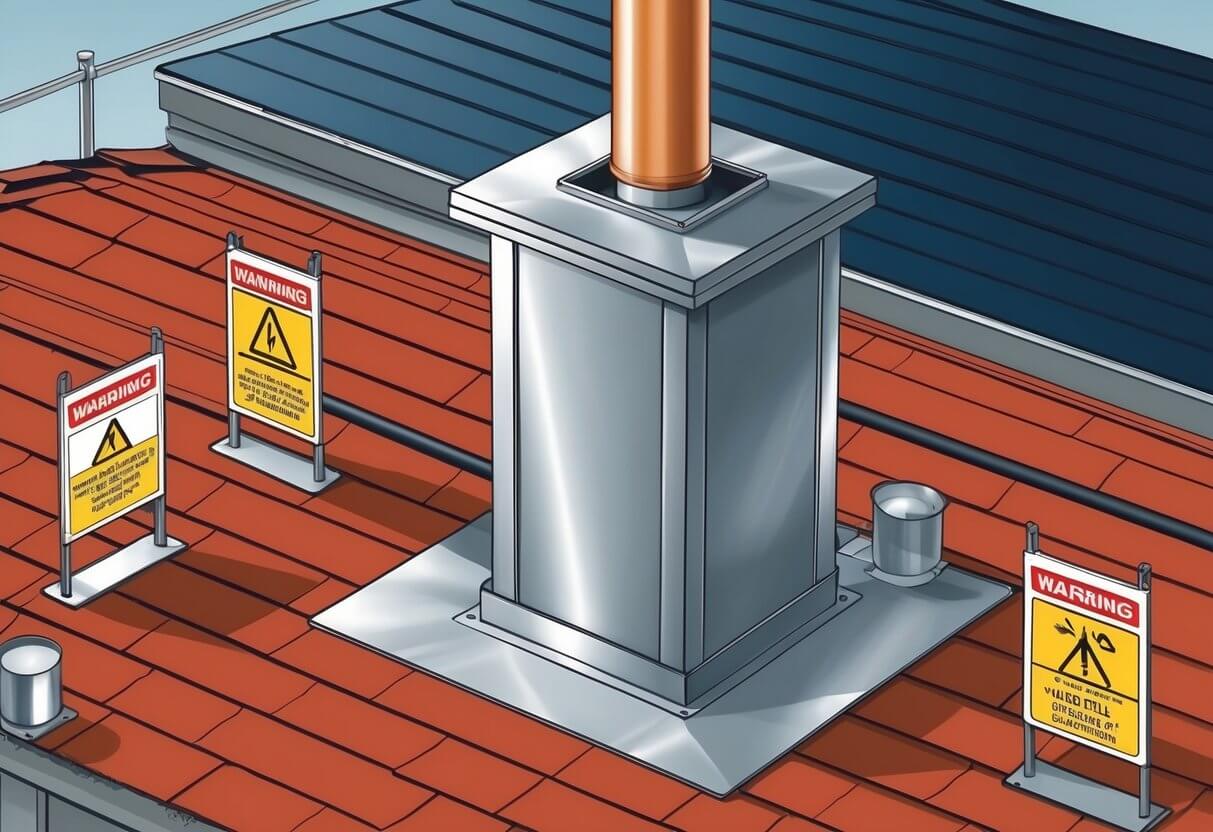

Compliance with Building Codes

Adhering to local building codes is essential for ensuring the safe operation of chimney flues. Each jurisdiction has specific regulations that cover the installation and maintenance of chimney systems.

We must prioritize the following:

- Flue Sizing: As per regulations, flue areas must match or exceed the connector area from appliances.

- Material Standards: Flue materials must withstand high temperatures, typically 1,800°F or more.

- Structural Integrity: Chimneys must be free of obstructions and damage.

By complying with these codes, we protect not only our property but also the well-being of those around us.

Installation and Types of Liners

When selecting and installing a chimney flue liner, we should consider various liner types and the specific installation procedures necessary for each. The choices we make can significantly impact the safety, efficiency, and longevity of our chimney system.

Choosing the Right Liner

Selecting the appropriate chimney flue liner is crucial for ensuring proper venting and safety. We have several options, including:

- Clay Tile Flue Liners: Ideal for conventional wood-burning fireplaces. They are durable and provide good thermal insulation.

- Stainless Steel Liners: Suitable for gas, oil, and wood appliances. They offer versatility and are resistant to corrosion.

- Aluminum Flue Liners: Best for medium-efficiency gas systems. They are the most affordable but less durable than stainless steel options.

To choose effectively, we should assess our heating system, the type of fuel used, and the condition of the existing chimney.

Liner Materials

The primary materials used for chimney liners each have distinct characteristics that affect their performance:

- Clay Tile: Known for their heat resistance and durability, clay chimney flue liners provide excellent protection against chimney fires but may crack under thermal stress.

- Stainless Steel: These liners are preferred for their strength and longevity. They can handle high temperatures and corrosive gases, making them the go-to for modern systems.

- Aluminum: Lightweight and cost-effective, aluminum is best for specific applications but lacks the robustness needed for high-efficiency or high-heat systems.

Other materials, such as cast-in-place liners, are also available, but we should consider their specific application requirements.

Installation Procedures

Installing a chimney liner involves several critical steps to ensure proper functionality and safety:

- Inspection: Begin by inspecting the existing chimney for damage or blockages.

- Cleaning: Clear away any soot, creosote, or obstructions to prepare the flue for the new liner.

- Sizing: Determine the appropriate size for the liner, which should match the flue’s dimensions.

- Placement: Install the liner, ensuring it fits securely within the chimney.

- Sealing: Finally, seal all joints and gaps to prevent any gas leaks, which protects against hazardous emissions.

By following these procedures, we can ensure the effective and safe operation of our chimney systems.

Maintenance and Inspection

Effective maintenance and inspection of flue chimneys ensure safe operation and optimal performance. Consistent cleaning and professional inspections are essential for identifying issues early and keeping our heating systems functional.

Regular Cleaning and Upkeep

We recommend regular chimney sweeping to prevent dangerous blockages of smoke and gases. Accumulation of creosote can significantly increase fire risks. A good practice is to clean the chimney at least once a year, especially for frequent users, such as those with a gas fireplace or wood-burning stove.

Steps for Cleaning:

- Inspect: Check for any visible debris.

- Clear Blockages: Use a chimney sweep brush and rods.

- Check chimney flue liners: Ensure they are in good condition.

Regular maintenance also involves checking the damper to ensure it opens and closes properly. This helps with airflow during operation and keeps unwanted drafts out.

Professional Inspections

We should schedule professional chimney inspections every few years to identify potential issues. Certified chimney sweeps conduct thorough assessments, examining the chimney’s exterior and flue condition. They look for cracks in the masonry and any signs of structural damage that may not be visible.

Levels of Inspection:

- Level 1: Basic examination, suitable for well-maintained chimneys.

- Level 2: More detailed, includes evaluation of hidden components and flue suitability.

This proactive approach can save us from costly repairs down the line.

Identifying and Repairing Damage

We must be vigilant in identifying signs of damage in our chimney system. Look for:

- Cracks or deterioration in the chimney structure

- Damaged chimney flue liners

- Signs of moisture inside the chimney

When we notice these issues, timely repairs are crucial. Repairing or replacing the flue liner can enhance safety and efficiency.

Engaging a professional for chimney repairs ensures proper fixes and adherence to safety standards. Ignoring damage can lead to serious hazards, such as chimney fires or the release of harmful fumes into our homes.

Advanced Concepts

In this section, we explore crucial concepts related to chimney flues that enhance their functionality and efficiency. These include the stack effect, which influences the movement of exhaust gases, and considerations for systems utilizing multiple flues.

Understanding the Stack Effect

The stack effect is the phenomenon where warm air rises, creating a pressure difference that helps to draw combustion by-products up through the chimney. When we burn fuel, the exhaust gases generated are less dense than the cooler air outside.

This density difference coupled with temperature variations enhances the upward draft in the flue.

Factors such as chimney height, temperature differential, and outdoor conditions can significantly affect this process.

To optimize the stack effect, we should ensure our chimney is adequately sized and free from blockages. Regular maintenance helps prevent issues like creosote buildup, which can impede airflow and pose a fire risk.

Dealing with Multiple Flues

When dealing with multiple flues, we must consider the interaction between them and the overall efficiency of our heating systems. Each flue serves its purpose, venting exhaust gases from different appliances.

It is vital to ensure that the flue serving each appliance is appropriately sized and installed.

We should also maintain clear separation between flues to prevent cross-contamination of exhaust gases. A chimney cap can aid in preventing downdrafts while protecting the integrity of each flue.

Proper venting and sizing are critical to avoid issues like backdrafts, which can lead to dangerous situations, including the potential for carbon monoxide intrusions into living spaces.

Frequently Asked Questions

In this section, we will address common inquiries regarding flue chimneys, covering installation, usage practices, maintenance considerations, and the benefits of various materials. Understanding these aspects can enhance safety and performance.

How is a flue chimney installed?

To install a flue chimney, we begin by selecting an appropriate location connected to the fireplace. Accurate measurements and alignment with building codes are crucial. The installation involves securing the chimney pipes and ensuring proper ventilation, with the flue lining inserted to facilitate safe exhaust of gases.

Should the fireplace flue be open or closed during use?

During the use of a fireplace, the flue should be open to allow smoke and harmful gases to exit safely. Closing the flue while the fireplace operates can lead to smoke backup, posing a fire hazard and potentially causing carbon monoxide exposure.

When should a flue chimney be replaced?

We should consider replacing a flue chimney if we notice signs of deterioration, such as cracks, excessive creosote buildup, or higher frequency of issues like drafts. Regular inspections can help identify these problems early, ensuring safety and effectiveness.

What is the purpose of a chimney damper?

The chimney damper serves to regulate airflow within the flue. By controlling the opening and closing of the damper, we can enhance energy efficiency, prevent heat loss when the fireplace is not in use, and minimize cold drafts from entering the home.

What are the typical costs associated with chimney flue installation?

Costs for chimney flue installation can vary significantly based on factors such as materials, labor, and local regulations. On average, we may expect prices to range from a few hundred to several thousand dollars, depending on the complexity of the installation and the type of chimney system chosen.

What are the advantages of a clay flue liner compared to other materials?

Clay flue liners offer several benefits, including resistance to heat and corrosion. They are also lightweight and provide excellent insulation. Compared to metal liners, clay options can enhance durability and longevity, making them a preferred choice in many chimney systems.

We Ship Anywhere USA & Canada

We Ship Anywhere USA & Canada